- Razor Shark - Lapping Fluid (RS-LF-500)

- Razor Shark - Lapping Fluid (RS-LF-500)

-

Diamond Lapping Fluid - 500ml (25-LF-500)

- Available Now

- £32.00

Diamond

Lapping Fluid 500ml Bottle

(25-LF-500)

- FREE UK Delivery

- Lapping Fluid 500ml Bottle Size.

- Suitable for use with all quality diamond abrasive products.

- Use instead of water to reduce the threat of rusting by upto 95%.

- Reduces possibility of clogging and improves diamond performance.

- WD-40 or other such lubricants are too thick and result in the tool skating over the diamond surface whilst sharpening

Why Use Razor Shark - Professional Lapping Fluid.

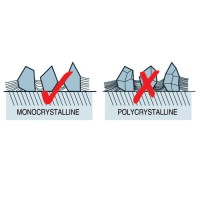

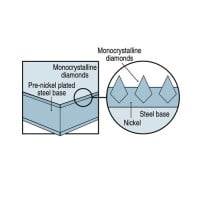

Our Professional grade diamonds whetstones are all individually handmade using Element 6 Monocrystalline Diamonds that are electroplated to the surface of a precision ground Steel plate using the metal Nickel as  the diamond cladding and bond, which supports the diamonds throughout the entire life of the whetstone, much like an Iceberg floating in the ocean – in the case of our whetstones there would be, 1/3rd showing above the surface of the water and 2/3rds being below the surface of the water. If you replace the word ‘Water’ for the word ‘Ice’ and then the word ‘Ice’ the word ‘Nickle’ and you will hopefully get the picture!

the diamond cladding and bond, which supports the diamonds throughout the entire life of the whetstone, much like an Iceberg floating in the ocean – in the case of our whetstones there would be, 1/3rd showing above the surface of the water and 2/3rds being below the surface of the water. If you replace the word ‘Water’ for the word ‘Ice’ and then the word ‘Ice’ the word ‘Nickle’ and you will hopefully get the picture!

Since Nickel is a water porous metal, much like a sponge, the use of water as a lubricant for our professional diamond whetstones is not advised. Nickle can easily hold and trap water like a sponge within its structure, which can quickly begin to undermine the stability of the diamonds that are embedded within the Nickle bonding layer.

Since Nickel is a water porous metal, much like a sponge, the use of water as a lubricant for our professional diamond whetstones is not advised. Nickle can easily hold and trap water like a sponge within its structure, which can quickly begin to undermine the stability of the diamonds that are embedded within the Nickle bonding layer.

Being water porous Nickle cannot prevent the supportive Steel bedding plate from rusting should it become exposed to excessive amounts of water that it would hold should water be used as a lubricant. It would be like wetting a Sponge and placing it on some unprotected Steel to dry off – the Steel would obviously begin to rust where the sponge sat on the surface. Once this rusting process begins to happen the rusted steel will flake thus causing the diamond/nickel electroplating to lose cohesion and fall off.

Whilst our whetstones are guaranteed for 5 years against workmanship and abrasive deterioration, this kind of damage is not what you want to happen to high quality diamond whetstones. If this does happen to your whetstone it will nullify your 5-year warranty.

Please Note: - It is, therefore, strongly advised that you Never use water as a lubricant, however, if you occasionally do, you are advised to always dry off the whetstone thoroughly after each use and never store your whetstone in a sealed or airtight container, such as a plastic bag or box etc. And please bear in mind that since Nickel is porous to water it will still hold onto the moisture that is absorbed in its surface, this can significantly reduce the life of these Professional quality whetstones and as already mentioned can limit the validity of your 5 year guarantee.

As an alternative to water and the issues it has with metal, we would always recommend that you use our Professional Lapping Fluid. Available in four sizes 50ml, 100ml, 250ml and 500ml our Professional Lapping Fluid has been developed over thirty years in the engineering industry for the sole purpose of being used on diamond sharpening products. It will prevent the threat of rusting and is able to lift swarf away from the diamond surface, which increases efficiency by preventing the surface from clogging. It will seal the microscopic pores of the Nickel preventing atmospheric moisture from entering, which will considerably prolong the effectiveness and durability of the diamond whetstone.

As an alternative to water and the issues it has with metal, we would always recommend that you use our Professional Lapping Fluid. Available in four sizes 50ml, 100ml, 250ml and 500ml our Professional Lapping Fluid has been developed over thirty years in the engineering industry for the sole purpose of being used on diamond sharpening products. It will prevent the threat of rusting and is able to lift swarf away from the diamond surface, which increases efficiency by preventing the surface from clogging. It will seal the microscopic pores of the Nickel preventing atmospheric moisture from entering, which will considerably prolong the effectiveness and durability of the diamond whetstone.

Razor Shark - Professional Lapping Fluid and Japanese Water Stones

Razor Shark - Professional Lapping Fluid is soluble in water, which is important when using your Diamond Whetstones to flatten your Japanese Water Stones. Since our Lapping Fluid is soluble in water, it will leave no oily residue on your Japanese Water Stone once the stone has been flattened on your Diamond whetstone. Any Lapping Fluid that is transfers over will either evaporate or be dissolved in the water the next time you wish to sharpen your tools using the Japanese Water Stones.

Just add some of the Lapping Fluid to the Diamond whetstone and flatten your Water/Oil Stone on the Diamonds. Since the Diamond whetstone surface is precision ground flat it will leave your water/oil stone precision flat as well.

To remove the Water/Oil Stone grit particles, after flattening the stone on your Diamond Whetstone, simply add some more Lapping Fluid to the Diamond whetstone, rub it in to lift the stone grit particles, and then rub it all off with a cloth. If you then use a rubberized cleaning block to finish cleaning the whetstone you will remove all remaining traces of the water/oil stones grit particulates and thus rejuvenate the surface of the Diamond whetstone.

Razor Shark Professional Lapping Fluid FAQ’s

Q: Do I have to use a lubricant when using diamond sharpening equipment?

A: The basic answer to this question is ‘Yes!’

In almost every sharpening case you come across you will need to use some kind of whetstone lubricant. A lubricant is usually needed to keep the surface of the whetstone clear of the build-up of swarf that is abraded from the tool you are sharpening.

Q: Is there a lubricant that you would recommend?

A: Water has become the lubricant of choice for most users of diamond whetstone, and as a lubricant it is freely available to all, certainly it is much better than using oils which are often overly thick and sticky, they are also dirty and extremely messy to use. If you inadvertently use an oil that is not specifically designed for whetstone sharpening such as a drying oil for example, as in some cooking oils or heaven forbid Linseed oil, you will cause a sticky oil film to build up which will drastically reduce or even prevent the diamonds from abrading anything.

Using water as your choice of lubricant is great if you are out and about in the great outdoors for a couple of days or so, however as has already been stated (above) it does have its drawbacks, it is well known that water and metal do not mix, since one will cause the other to rust.

Q: What is our Professional Lapping Fluid made from?

A: Razor Shark - Professional Lapping Fluid like oil, is a petroleum based product, however unlike oil should our Lapping Fluid be left on the surface of the diamond whetstone, for whatever reason, will eventually evaporate over period of about 30 to 40 minutes … this oil will not do.

Oil, being somewhat sticky, will attract dust and other forms of debris from the air and surrounding work benches etc, which will clog up the whetstone surface thus reduce abrasive efficiency and if a drying oil is used you may be required to use harsh chemicals to remove the resulting film; if using water or water based products you will eventually have issues with rusting. Razor Shark - Professional Lapping Fluid will not cause any of these problems.

Q: Can I use the Razor Shark - Professional Lapping Fluid on any diamond whetstone?

A: It is recommended that our Professional Lapping Fluid be used on any type of diamond whetstone, regardless of manufacture or construction.

Q: There is a five year guarantee on all of your Razor Shark - Sharpening Diamond Whetstones; however, if I do not use this lapping fluid will it affect this guarantee?

A: Yes, as I have already explained using other forms of lubricant can cause problems with the whetstone, these issues are not covered by the five years guarantee that we offer. This effectively means that if your whetstone begins to rust and therefore lose the diamonds that make it a Razor Shark - Diamond Whetstone, We cannot replace the stone. As long as our Professional quality Diamond Whetstones are used in accordance with our usage instructions this five year guarantee will be honoured.

Q: Can I use a very light oils, such as WD40 as a lubricant?

A: No, not really. Basically even very light oils of this nature are still too thick and stick to be used on whetstones of this quality. For example, the Fine side of a Trend Whetstone uses a diamond particulate size of approximately 20 microns, which is 2.5 to 3 times smaller than a human hair cut across its diameter. And when the diamond is electroplated to the steel base plate within its blanket of nickel only the top one third of the diamond will stand proud of the surface; since two thirds of the diamonds 20 microns will be embedded within the nickel, this leave about 7 microns exposed. WD40 or other very light oils will prevent efficient sharpening to take place, by causing the tool to just ‘Skate’ over the surface … after all isn’t that what oil is used for - reducing friction between two surfaces?

We strongly advise the use of Diamond Abrasive Lapping Fluid on all of your Diamond Whetstones.

We strongly advise the use of Diamond Abrasive Lapping Fluid on all of your Diamond Whetstones.

Originally developed solely for use with diamond abrasives, this special Lapping Fluid has been used for more than 30 years in the engineering industry, by allowing much greater efficiency whilst sharpening. Once a small amount is applied it lubricates the surface of the Diamond Whetstone, which not only helps alleviate surface clogging with abraded metal, but also prevents the tool from slidingand skating across the surface because it is too thick and slippery. The Diamond Abrasive Lapping Fluid evaporates after use and helps prevent rusting.

Lapping Fluid and Japanese Waterstones

Protects your five year guarantee with Razor Shark - Diamond Abrasive Lapping Fluid.

PLEASE NOTE: All of the Tools that are shown in the above photos are not included in this sale.

More information about our exclusive Razor Shark Diamond Sharpening System visit our Articles & Tips