- Razor Shark - Continuous Surface 6-Inch by 2-Inch Double-Sided Bench Stone

- Razor Shark - Continuous Surface 6-Inch by 2-Inch Double-Sided Bench Stone

- Razor Shark - Continuous Surface 6-Inch by 2-Inch Double-Sided Bench Stone

6 x 2 Inch Continuous Surface Double Sided Bench Stone - 300/1000 grit (25-W6-FC)

- From £49.00

Continuous Surface Diamond Whetstone is used to sharpen Plane Blades, Chistles & Gouges and Tungsten Carbide Tools plus a whole lot more besides.

- Continuous Surface Diamond Coating prevents snagging when sharpening small or pointed tooling.

- Precision flatness.

- Fine 1000 grit (15 micron) and coarse 300 grit (50 micron).

- Grades are marked on stone.

- Guaranteed for five years.

- Recommended use with Razor Shark lapping fluid to prevent clogging or rusting and assist in keeping tools clean.

- Use with no pressure.

- Ideal for flattening chisels and plane blades as well as achieving a shaving edge in seconds.

- Precision flatness gives the ability to also sharpen spindle knives in house.

- The extra coarse grit is suitable to fix and restore a damaged edge on chisels, plane irons.

- Users include Rolls Royce & British Aerospace.

6" x 2" Continuous Surface Double Sided Bench Stone (25-W6-FC) Includes:

1 x 6" by 2" Continuous Surface Double Sided Bench Stone (25-W6-FC)

1 x Storage pouch

Whetstone Specifications:

- Size: 6” x 2” x 5/16”

- Size: 152 mm x 50mm x 8 mm

- Grade: Fine & Coarse

- Grit: 1000 & 300 (nom. 15 & 50 micron)

- Diamond Grade: De Beers - Element 6 - Monocrystalline Diamonds

The 6" x 2"  Continuous Surface Double Sided Bench Stone is one the most useful and unique Monocrystalline diamond Whetstones there is on the market today. It is 2 inches wide and 6 inches long making it ideal for sharpening all of your workshop, kitchen and outdoor tools. The bench stone has two Grit/Mesh sizes, the Coarse 300 grit (50 micron) removes metal quickly and efficiently when tools are extremely dull or damaged, whilst the 1000 grit (15 micron) is ideal for everyday sharpening of tools when they are in need of a quick hone just to maintain the cutting edge. The continuous diamond surfaces allow smaller tools such as router bits, pen knives, scalpels and even fishing hooks can be sharpened with ease.

Continuous Surface Double Sided Bench Stone is one the most useful and unique Monocrystalline diamond Whetstones there is on the market today. It is 2 inches wide and 6 inches long making it ideal for sharpening all of your workshop, kitchen and outdoor tools. The bench stone has two Grit/Mesh sizes, the Coarse 300 grit (50 micron) removes metal quickly and efficiently when tools are extremely dull or damaged, whilst the 1000 grit (15 micron) is ideal for everyday sharpening of tools when they are in need of a quick hone just to maintain the cutting edge. The continuous diamond surfaces allow smaller tools such as router bits, pen knives, scalpels and even fishing hooks can be sharpened with ease.

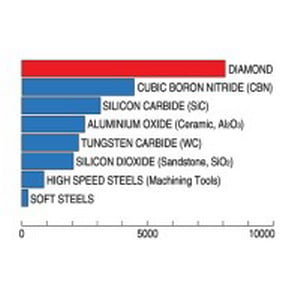

The 6" x 2" Continuous Surface Double Sided Bench Stone is made from pure De Beer - Element 6 - Monocrystalline diamonds, which are considered to be the very best abrasive diamonds in the world. And since diamonds are approximately 20 times harder than steel they have the versatility to sharpen any, and all, of your tools no matter how dull they become or hard the material. Element 6 Monocrystalline will skate through Tungsten and Ceramic tools or blades.

The 6" x 2" Continuous Surface Double Sided Bench Stone is made from pure De Beer - Element 6 - Monocrystalline diamonds, which are considered to be the very best abrasive diamonds in the world. And since diamonds are approximately 20 times harder than steel they have the versatility to sharpen any, and all, of your tools no matter how dull they become or hard the material. Element 6 Monocrystalline will skate through Tungsten and Ceramic tools or blades.

The 6" x 2" Continuous Surface Double Sided Bench Stone is capable of doing a thousand and one sharpening jobs in the workshop, the house, the garden or when out in the field.

What can the 6" x 2" Continuous Surface Double Sided Bench Stone Sharpen?

The 6" x 2" Continuous Surface Double Sided Bench Stone glide through the toughest of metals, such as Ceramic Blades, Tungsten, Hardened Tool Steel and Stainless Steel, so it will easily sharpen: Knives, Axes, Machetes, Woodturning Gouges, Bevel Edges, Skews, Carving Tools, Scalpel Blades, Model Engineering Tools, Routers, Chain Saws, Saw Blades, Small Chisels, Large Chisels, Serrated Cutting Edges, Shears, Fishing Hooks and a whole lot more besides.

The 6" x 2" Continuous Surface Double Sided Bench Stone glide through the toughest of metals, such as Ceramic Blades, Tungsten, Hardened Tool Steel and Stainless Steel, so it will easily sharpen: Knives, Axes, Machetes, Woodturning Gouges, Bevel Edges, Skews, Carving Tools, Scalpel Blades, Model Engineering Tools, Routers, Chain Saws, Saw Blades, Small Chisels, Large Chisels, Serrated Cutting Edges, Shears, Fishing Hooks and a whole lot more besides.

Why?

Because diamonds are not just a girl’s best friend they are the Sharpeners best friend as well. Diamonds are the hardest known natural substance identified by man. Being about 20 times harder than Steel they will easily sharpen the toughest of blades.

Because diamonds are not just a girl’s best friend they are the Sharpeners best friend as well. Diamonds are the hardest known natural substance identified by man. Being about 20 times harder than Steel they will easily sharpen the toughest of blades.

In fact Diamond abrasives are so hard that they are used to sharpen Ceramic Blade, and if they can sharpen ceramic tools they will have no problems with Tungsten Carbide and if they have no problems with Tungsten Carbide they will positively wiz through High Speed Steel or any knife or cutting tools that you have like a hot knife through warm butter!

Diamond Grits Sizes

Extra Fine (EF) - Extra Fine Diamond whetstones are made from 1,000 grit/mesh sized diamonds that measure 15 microns in size. Just a few strokes, on a 1,000 grit whetstones will bring a slightly dulling blade back a Razor Sharp cutting edge that will pop the hairs off your arm with ease - assuming you have them that is ... sorry ladies!

Fine (F) - Fine diamond whetstones are 600 grit/mesh particle sized diamonds, which means that they are 25 microns in size. Fine diamond whetstones are ideal for putting a super sharp cutting edge on blades that are regularly maintained (i.e. they are perfect for restoring any knife or tool that has just started to become slightly dull). This restoration, more often than not, is accomplished within just one or two strokes across a Fine whetstone.

Coarse (C) - Coarse diamond whetstones are 340 grit/mesh particle sized diamonds, which means that they are 45 microns in size. Coarse diamond whetstones are general used for rapidly honing and restoring dull or damaged edges on neglected tools, blade and general cutting tools such as joinery and High Speed Steel tooling, bringing them back to a sharp cutting edge again, also for re-shaping and rapid metal removal, fast action cutting, without worry of edge refinement.

Extra Coarse (XC) - The Extra Coarse diamond whetstones use 180 grit/mesh diamond particles, which are 76 microns in size. This size of grit will remove metal at a very fast speed making it ideal for restoring broken points, removing chips from badly damaged or very dull blades and for fast knife sharpening where a burr is required in double time.

Types of Diamond - Monocrystalline vs. Polycrystalline

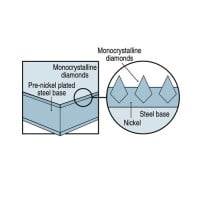

Razor Shark Diamond Whetstones are renowned for their remarkable sharpening speed. This sharpening speed is a function of the quality of the micronized super abrasive, Monocrystalline Diamond that they use in all of our products.

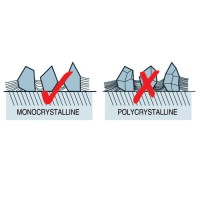

Picture (left) demonstrates the how Monocrystalline Diamond

Picture (left) demonstrates the how Monocrystalline Diamond

Crystals (Picture left) look like under a microscope compared to

Polycrystalline Diamond Crystals (Picture right). It becomes obvious that the Polycrystalline diamonds will begin to fracture at the weakest points, which are shown where the surface is segmented. Whereas the Monocrystalline diamonds have no such flaws and will not therefore fracture when used.

Polycrystalline Diamonds

Polycrystalline Diamonds are weak diamonds that easily fragment when used, but are still widely used in many of the cheaper diamond whetstones because they are so very cheap to produce.

Polycrystalline diamond are made in such a way that the process causes the diamonds to have microscopic flaws and fracture lines that are very weak and will therefore fragmented when used. Polycrystalline diamond sharpening compounds rapidly break and wear away thus reducing the Grit size of the whetstone as they are used.

Many competitors use Polycrystalline diamonds; these diamonds will easily breaks apart, sometimes within minutes of use, fragmenting into a paste that is instantly washed away by any lubricant that is used. Some competitor’s even claim that their stones are constructed from multiple layers of diamonds, however, this only indicates the poor quality diamonds that being used. After all using high quality Monocrystalline diamonds on surface that is designed to wear away revealing new diamonds underneath would be a waste of these quality diamonds, since they will only be washed away.

A word of Caution! Low quality Polycrystalline diamonds are used in cheaper versions of diamond stones. These Polycrystalline diamonds are inherently flawed, causing them to quickly fragment and shatter upon use, this fragmentation effectively, changes the nature of the diamond stones grit size value, reducing the overall grinding speed and efficiency. What is worse than this is that with little continued use these cheap Polycrystalline diamonds continue to shatter until they have simply disintegrated away to nothing. In the world of diamond sharpening, you really do only get what you pay for. Polycrystalline diamonds are simply not fit for the job and will be a waste of your hard earned money.

Monocrystalline Diamond

Monocrystalline Diamonds are manufactured by ‘Element 6 Diamonds,’ a company that is renowned for its super-abrasives and advanced diamond products. We only use Element 6 Monocrystalline Diamonds in our range of Razor Shark Whetstones simply because they are superior, stronger and have a single crystalline structure. Our pure unflawed Monocrystalline diamond will not shatter or break down with use, we guarantee it.

Monocrystalline Diamonds are manufactured by ‘Element 6 Diamonds,’ a company that is renowned for its super-abrasives and advanced diamond products. We only use Element 6 Monocrystalline Diamonds in our range of Razor Shark Whetstones simply because they are superior, stronger and have a single crystalline structure. Our pure unflawed Monocrystalline diamond will not shatter or break down with use, we guarantee it.

Since our Monocrystalline diamonds are so very strong they have an exceptionally long life span, which means that they will have paid for themselves many times over when compared to the cheaper Polycrystalline brand of whetstone that are out there. As the saying goes ‘Caveat Emptor’ (Let the buyer beware), because in the Diamond Sharpening field, you most certainly get what you pay for.

So, when only the very best will do, opt for Razor Shark Monocrystalline Sharpening Equipment.

Razor Shark Monocrystalline Diamonds Have The Following Properties:

- Fast - Hardest material, the most efficient sharpening abrasive.

- Easy - Light pressure produces an edge in seconds.

- Clean - Use with Trend lapping fluid to prevent rusting or clogging. Oils are too thick.

- Versatile - Sharpens all hard materials including Tungsten Carbide & high speed steel.

- Durable - Stays flat & has a long life.

Why not add some

Diamond Abrasive Lapping Fluid?

(RS-LF-50/100/250/500)

- Available in four sizes 50ml, 100ml, 250ml and 500ml.

- Suitable for use with all quality diamond abrasive products.

- Use instead of water to reduce the threat of rusting by 95%.

- Reduces possibility of clogging and improves diamond performance.

- WD-40 or other such lubricants are too thick and result in the tool skating over the diamond surface whilst sharpening.

We strongly advise the use of Diamond Abrasive Lapping Fluid on all of your Diamond Whetstones. Diamond Abrasive Lapping Fluid is available in four sizes 50ml, 100ml, 250ml and 500ml and it is very economical, since only a small dribble is required to lubricate a whole Diamond whetstone.

We strongly advise the use of Diamond Abrasive Lapping Fluid on all of your Diamond Whetstones. Diamond Abrasive Lapping Fluid is available in four sizes 50ml, 100ml, 250ml and 500ml and it is very economical, since only a small dribble is required to lubricate a whole Diamond whetstone.

Originally developed solely for use with diamond abrasives, this special Lapping Fluid has been used for more than 30 years in the engineering industry, by allowing much greater efficiency whilst sharpening.  Once a small amount is applied it lubricates the surface of the Diamond Whetstone, which not only helps alleviate surface clogging with abraded metal, but also prevents the tool from slidingand skating across the surface because it is too thick and slippery. The Diamond Abrasive Lapping Fluid evaporates after use and helps prevent rusting.

Once a small amount is applied it lubricates the surface of the Diamond Whetstone, which not only helps alleviate surface clogging with abraded metal, but also prevents the tool from slidingand skating across the surface because it is too thick and slippery. The Diamond Abrasive Lapping Fluid evaporates after use and helps prevent rusting.

PLEASE NOTE: All of the Tools that are shown in the above photos are not included in this sale.

More information about our exclusive Razor Shark Diamond Sharpening System visit our Articles & Tips